While COP27 falls short of expectations, epoxies continue to deliver for a greener future

The recently concluded COP27 summit produced some results, in the sense that financial aids have been promised to countries being hit hardest by the ongoing climate change. However, it fell short on producing firm commitments by the industrialized part of the world to cut back on fossil fuels and carbon dioxide emissions to steer the world back to the 1.5-degree C. path.

The energy sector is responsible for more than 75% of the EU’s greenhouse gas emissions. Increasing the share of renewable energy across the different sectors of the economy is therefore a key building block to reach the EU’s energy and climate objectives1.

Epoxies play a key role making renewable energy sources durable and resilient.

In the wind energy sector, the blades of turbines are made durable with epoxy infusion and adhesive systems, thanks to their high strength to weight ratio, load bearing capacity, and damage tolerance.

The burgeoning hydrogen industry, which converts surplus electric power production of offshore wind farms into green hydrogen, is benefiting from epoxy composite reinforced pressure tanks and vessels which are needed to store and transport hydrogen gas. Hydrogen gas can replace methane gas in industrial processes thus contributing to the decarbonization of European industries.

Hydro power plants, quite often operating in hostile environments, need their concrete dam structures being protected against the onslaught of the elements for long-term, reliable energy output. Epoxy enhanced concrete mortars shield them against the erosive impact of constantly lashing water. They provide non-permeability, high load bearing capability and excellent wear resistance.

The still fast-growing transportation sector also has a key role to play in pushing the needle in the right direction. Cutting down carbon emissions from transportation could reduce greenhouse gas emissions by 60% in Europe by 2050. In 2030, the CO2 standards in Europe will require more than a third of car sales to be electric, whereas to meet 2050 climate goals, all vehicles sold will have to emit zero emissions by the early 2030s.

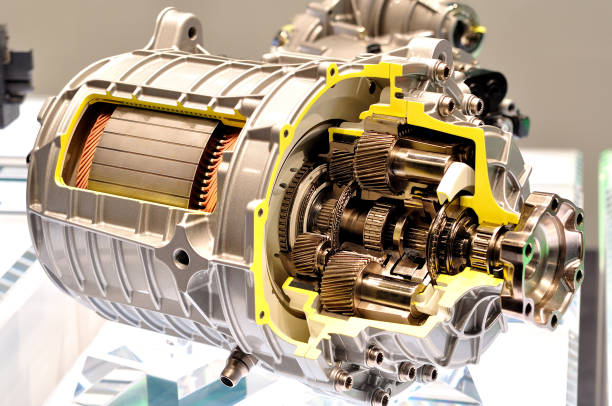

Epoxies will be vital for driving this transition towards e-mobility by making our future cars more energy-efficient, durable, and safer to drive. Composite structures, being it the whole car body or specific structural components like tailgates, hoods, roofs, etc., in general contribute to the desired light-weighting of car bodies. This helps offsetting some of the weight burden of still heavy battery packs. But the benefits of epoxies do not stop there but extend to electric battery cages and electric motors as well.

In the future, magnet less motors will be the preferred choice to avoid rare earth-metal based permanent magnets. These motors operate at high rotational speeds which can go up to 20 000 revolutions per minute. Preventing motor imbalance and ultimately destruction, the rotor coils must be impregnated with a material providing high mechanical strength and excellent crack resistance at the required high operating temperatures of 150 – 200C.

And yes, by now you’ve guessed it…for this task Epoxy resins are the material of choice!