The selection of the reactants, the mixing ratio, and the curing process itself will determine many properties of the cured epoxy resin, like its adhesion to other materials, its mechanical strength, its thermal and chemical resistance or its dielectric strength.

Minute residual traces of BPA are left in epoxy resin as impurities from resin production. These traces, also known as technical impurities, will either react during the curing process or will be embedded and thus immobilised into the cured resin matrix.

This process also prevents a release during service life. At the end of the use period, incineration in refuse incineration plants, cement kilns, or steel foundries (recycling of coated steel) is a common disposal form. The recycling of epoxy-based polymers is a challenge due to their highly crosslinked thermoset nature and is still in its infancy. Grinding of cured epoxy polymers to powder and subsequent use as a filler is a possibility but represents only a low-value downgrading recycling option.

[TSZ1]

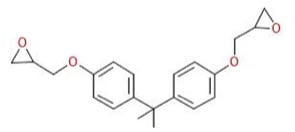

Cured Epoxy resins, in their simplest form, are built by mixing the starting components of epoxy resin and hardener in a specific mixing (stoichiometric) ratio to produce a thermoset polymer. The most widely commercialised resin of its kind is created by reacting Bisphenol A (BPA) and epichlorohydrin in a 2-step process, which results in its pure form as the basic monomer unit of an epoxy resin called BADGE – or DGEBA – short for Bisphenol A DiGlycidyl Ether. However, most liquid epoxy resins also contain higher molecular weight fractions like dimer, trimer or oligomer species in varying content, depending on the reaction conditions. BADGE is then mixed with hardeners and/or other reactive substances with which it undergoes a process called “curing” or “hardening” to constitute the final epoxy-based polymer.

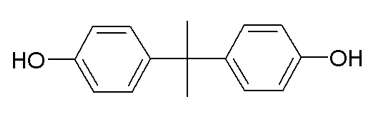

BPA

CAS 80-05-7

White solid

Solubility in water: 300 mg/l

Danger

BADGE

CAS 1675-54-3

Viscous liquid

Solubility in water: 6.9 mg/l

Warning

BISPHENOL A (BPA)

BPA is a starting substance for BADGE – also described as an intermediate -. However, BADGE is an entirely different molecule with its own unique properties, not just an aggregate of BPA + epichlorohydrin.

BPA is one of the most scrutinised substances worldwide.

REACH

REACH is a comprehensive regulatory framework adopted by the European Union in June 2007 to improve the protection of human health and the environment from the risks that can be posed by chemicals while enhancing the competitiveness of the EU chemicals industry.

REACH applies to all chemical substances: those used in industrial processes but also in our day-to-day lives. Therefore, the regulation has, directly or indirectly, an impact on most, if not all, companies across the EU.

Companies must identify and manage the risks linked to the substances they manufacture and market in the EU to comply with REACH. They must demonstrate how a substance can be safely used and communicate the risk management measures to the users.

If the risks cannot be adequately managed, authorities can restrict substance use in different ways. In the long run, the most hazardous substances, the so-called substances of very high concern, should be replaced with less hazardous alternatives.

EPOXY PRECURSORS

All registration dossiers are regularly updated.

Typical Epoxy Precursor or Epoxy building blocks are: Bisphenol A, Bisphenol F, Tetrabromo-Bisphenol A, Epichlorohydrin, Phenol, Formaldehyde, BADGE and many more. Epoxy Resins might use aliphatic or cycloaliphatic precursors or other molecules to modify the oligomeric or polymeric backbone to obtain particular physical properties.

The industry has a vital interest in providing up-to-date hazard and safe-use information to stay compliant and keep its employees and users safe to maintain a long-term sustainable future for all.

BADGE

CORAP 2015 CONCLUDED IN 2021:

The substance evaluation triggers listed were: Exposure/wide dispersive use, consumer use, aggregated tonnageHuman health/suspected CMR: Transgenic rodent assay completed. The results indicate no mutagenic activity in the duodenum, stomach or liver somatic cells.

The substance evaluation conclusion document from the 20th of May 2021 states:

“No need for regulatory follow-up action at EU level”

BPA – BADGE PRECURSOR

Authorisation:

BPA- has been proposed for prioritisation by ECHA in 2019, which in the future could lead to inclusion into Annex XIV, i.e. authorisation. Please note that BPA is used as a monomer in manufacturing epoxy resins, which is an intermediate use. The authorisation procedure would not address the manufacture of BPA or its use as an intermediate.

Envisioned Scope of materials impacted by a potential authorisation: A small percentage of hardeners containing elevated amounts of BPA as a curing accelerator and co-curing agent. These are used in highly specialised niche applications where they are hard to replace.

Restrictions:

BPA restriction and EFSA Opinion

BADGE REACH REGISTERED CAS-NR. CHANGED

Following a decision by the European Chemicals Agency (ECHA) in 2018, and in accordance with the REACH regulation (EC) No. 1907/2006, it is necessary to modify the “chemical identifiers” (Chemical Name, CAS Number, EC Number), for a range of low molecular weight Bisphenol A based epoxy resins.

Accordingly, several epoxy resin products can no longer be described as “Reaction products of Bisphenol-A and Epichlorohydrin”, and the new “chemical identifiers” shown below will be assigned:

| New substance ID | Old substance ID | |

| CAS name | Oxirane, 2,2′-[(1-methylethylidene)bis(4,1-phenyleneoxymethylene)]bis | |

| EC name | 2,2′-[(1-methylethylidene)bis(4,1-phenyleneoxymethylene)]bisoxirane | 4,4′-Isopropylidenediphenol, oligomeric reaction products with 1-chloro-2,3-epoxypropane |

| EC number | 216-823-5 | 500-033-5 |

| CAS number | 1675-54-3 | 25068-38-6 |

| REACH registration number | 01-2119456619-26-xxxx |

The Epoxy Europe members have initiated a transition project and have gradually updated their Safety Data Sheets (SDS) and labels of all the affected epoxy resin products.

Please note that while there is no impact on the product properties or classification, on receipt of an updated SDS, you should make sure to update your own SDS and/or update existing product notifications and certifications.

GERMAN WGK (RIGOLETTO) DATABASE

CAS No. 1675-54-3 for Bisphenol-A-diglycidylether (BADGE) has been assigned to the existing Water Hazard Class (WGK) under assignment no.2007 in addition to CAS no. 25068-38-6 by UBA.

Search – Rigoletto (uba.de)